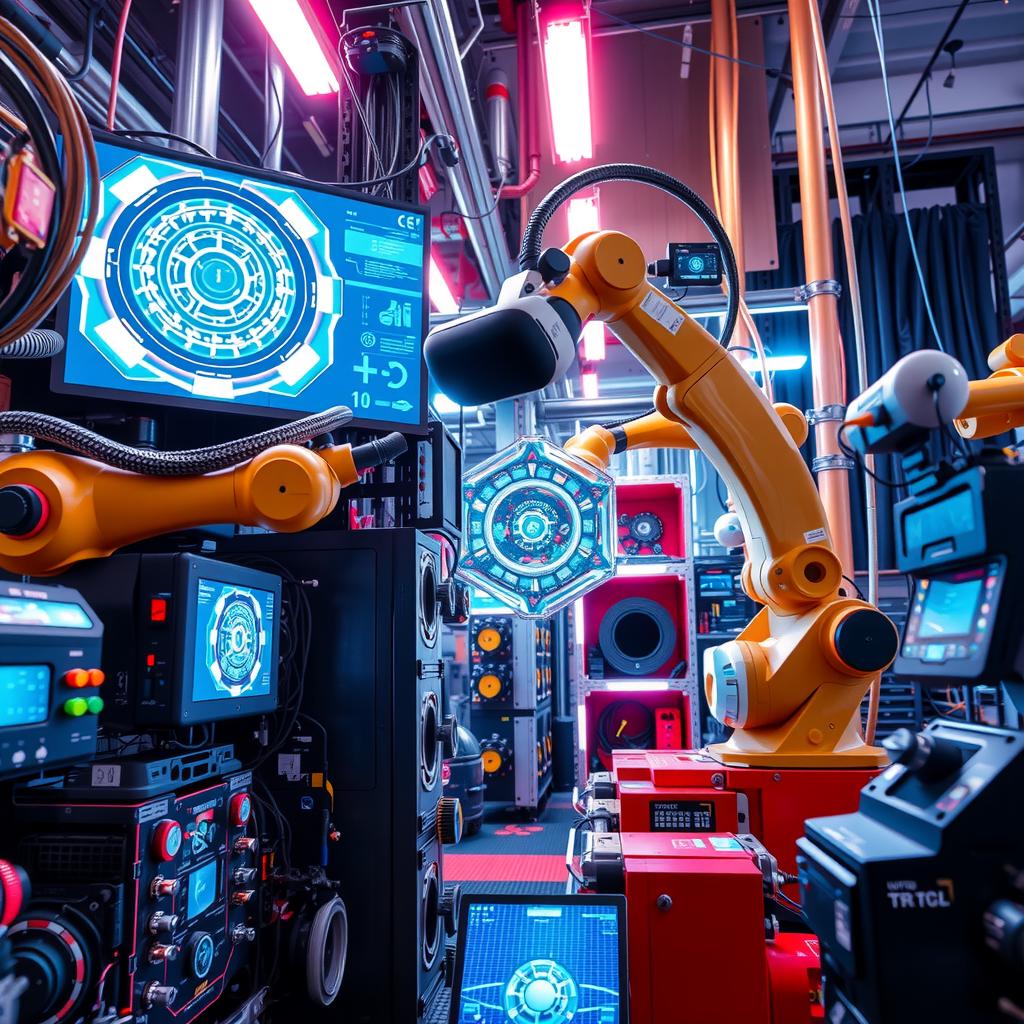

In the fast-evolving landscape of manufacturing, ensuring product quality while optimizing production efficiency remains a formidable challenge for many organizations. With increasing pressure to meet industry standards and customer expectations, traditional quality control systems often fall short in addressing the complexities of modern manufacturing processes. Enter VR manufacturing quality control systems, which leverage cutting-edge virtual reality solutions to revolutionize how manufacturers approach defect detection and process optimization. This innovative technology not only enhances accuracy but also fosters a more immersive understanding of production workflows.

The core value embedded within VR manufacturing quality control systems lies in their ability to transform data analysis from mere numbers into actionable insights that resonate on the shop floor. By simulating real-world environments through virtual reality, manufacturers can visualize potential defects before they occur, allowing teams to preemptively address issues that could derail productivity. Moreover, integrating automation technology with these VR solutions empowers businesses to streamline their operations and significantly reduce human error—a critical factor in maintaining high-quality output.

As organizations strive for greater adaptability amidst shifting market demands, embracing VR-based approaches becomes increasingly essential. The integration of such advanced manufacturing systems provides an unparalleled opportunity for enhancing operational agility while adhering closely to stringent industry norms. It invites professionals across sectors—from engineering teams focused on precision tools to managers overseeing large-scale production lines—to engage collaboratively in refining their processes.

By exploring how VR manufacturing quality control systems can be effectively implemented within existing frameworks, this article will delve into the transformative potential these technologies offer. Readers will discover strategies for utilizing virtual reality not just as a tool but as an integral component of a comprehensive quality assurance strategy that elevates both product integrity and organizational performance. The journey toward optimized production is unfolding—let’s examine how virtual reality stands at the forefront of this evolution.

Key points:

-

Enhanced Defect Detection: The integration of VR manufacturing quality control systems empowers manufacturers to detect defects in real-time. By utilizing immersive virtual environments, organizations can meticulously monitor production processes and identify potential issues before they escalate into costly problems. This proactive approach is essential for maintaining compliance with stringent industry standards, ensuring that products meet high-quality benchmarks consistently.

-

Streamlined Process Optimization: With the adoption of VR manufacturing, companies are now able to simulate various workflows and scenarios within a controlled setting. This capability allows for comprehensive data analysis, leading to significant improvements in production efficiency. By understanding how each stage of the production cycle operates in a virtual space, organizations can implement tailored strategies that enhance overall effectiveness while minimizing errors.

-

Comprehensive Staff Training: One notable advantage of employing virtual reality solutions within manufacturing systems is their ability to facilitate immersive training modules for employees. These programs enable staff to acquire new skills without disrupting ongoing operations, ultimately fostering a culture focused on continuous improvement. As personnel become adept at using the latest automation technology integrated into VR manufacturing quality control systems, they contribute significantly towards reducing risk and enhancing product quality across all operational levels.

Understanding the Shift in Manufacturing Standards

The Imperative for Enhanced Quality Control Measures

As the manufacturing landscape evolves, driven by rapid technological advancements and changing consumer expectations, the necessity for enhanced quality control measures becomes increasingly evident. The integration of VR manufacturing quality control systems is revolutionizing traditional practices, allowing manufacturers to uphold industry standards with greater efficiency. In an era where competition is fierce, companies are compelled to not only meet but exceed customer expectations through superior product quality. This shift towards a more proactive approach in defect detection has become essential; data analysis plays a pivotal role in identifying flaws early within production cycles, thus minimizing waste and reducing costs.

Embracing Automation Technology

With the rise of automation technology in manufacturing processes, organizations are witnessing significant improvements in production efficiency. VR manufacturing quality control systems leverage virtual reality solutions to simulate real-world scenarios that assist technicians in understanding potential pitfalls before they occur on the factory floor. This forward-thinking methodology allows teams to optimize their processes dynamically while adhering strictly to established industry standards. By employing advanced algorithms and machine learning techniques within these automated frameworks, businesses can identify anomalies and implement corrective actions at unprecedented speeds—ultimately leading to superior product outcomes.

Data-Driven Decisions Enhancing Quality Assurance

Incorporating robust data analysis into quality control protocols marks a transformative phase for modern manufacturers. Organizations utilizing VR manufacturing quality control systems benefit from real-time insights that facilitate informed decision-making throughout various stages of production. For instance, by analyzing historical performance metrics against current outputs, manufacturers can pinpoint inefficiencies or recurring defects quickly—enabling them to adjust operations proactively rather than reactively addressing issues post-production. As such methodologies cultivate a culture of continuous improvement among staff members while reinforcing accountability across departments.

Future-Proofing Through Innovative Solutions

Looking toward the future of manufacturing necessitates an unwavering commitment to innovation—particularly regarding enhancements in quality management strategies. Deploying VR manufacturing quality control systems positions companies not just as reactive players but as leaders prepared for emerging challenges within their sectors. By continuously refining inspection protocols through cutting-edge technology like augmented reality interfaces or predictive analytics tools tailored specifically for defect detection tasks, businesses solidify their standing amid constant market fluctuations while enhancing overall productivity levels.

In conclusion, as global economic dynamics evolve rapidly alongside technological innovations reshaping industries worldwide; prioritizing comprehensive strategies surrounding effective quality control cannot be overstated—the convergence between high-tech solutions such as VR applications alongside diligent process optimization efforts will define tomorrow’s success stories across diverse sectors today!

Revolutionizing Quality Control in Manufacturing

The Integration of VR Technology for Enhanced Defect Detection

The advent of VR manufacturing quality control systems has ushered in a new era within the realm of industrial processes, particularly emphasizing defect detection and process optimization. Virtual Reality (VR) technology allows manufacturers to simulate their production environments, enabling real-time monitoring and analysis that traditional methods simply cannot match. By immersing operators in a virtual setting, they can inspect products with unparalleled detail, identifying even the minutest defects that might go unnoticed during conventional inspections. This immersive experience not only enhances the accuracy of defect detection but also significantly reduces the time required for quality assessments. Furthermore, these systems utilize advanced data analytics capabilities to recognize patterns over time; thus facilitating proactive measures against recurring issues which may undermine production efficiency.

Streamlining Processes with Automation

Enhancing Workflow Efficiency through VR Solutions

In addition to improving defect detection, VR manufacturing quality control systems are pivotal in optimizing workflows across various stages of production. By integrating automation technology into these solutions, manufacturers can streamline their operations while adhering to industry standards more effectively than ever before. For instance, VR simulations allow teams to visualize complex assembly lines and identify bottlenecks or inefficiencies without interrupting actual operations on the floor. This proactive approach empowers decision-makers to implement adjustments swiftly based on accurate data-driven insights derived from their virtual models—ultimately enhancing overall productivity rates while minimizing wasteful practices associated with trial-and-error methodologies.

Training and Development: A Virtual Approach

Empowering Workforce Skills via Immersive Learning

Another significant benefit provided by VR manufacturing quality control systems lies in employee training and development programs tailored specifically for quality assurance roles within organizations. Traditional training techniques often fall short when it comes to practical application; however, incorporating VR provides workers with hands-on experience without exposing them or company assets to potential risks associated with real-life errors during training sessions. Employees can engage directly with simulated equipment scenarios where they learn best practices around defect identification or compliance checks relevant under current regulatory frameworks—all delivered through an engaging learning environment that reinforces retention rates among trainees considerably better than standard lectures or manuals could achieve alone.

In conclusion, as industries continue evolving towards greater efficiency and higher standards for product integrity amidst increasing competitive pressures globally—the adoption of innovative technologies like VR manufacturing quality control systems becomes indispensable for modern enterprises seeking sustainable growth strategies grounded firmly upon robust operational foundations built atop meticulous attention paid toward both human capital investment alongside technological advancements alike.

Future Implications: Continuous Improvement through Innovation

Enhancing Risk Management and Training with VR Solutions

The advent of virtual reality (VR) solutions presents a transformative opportunity for industries seeking to enhance proactive risk management and staff training methodologies. By integrating VR manufacturing quality control systems, organizations can simulate real-world scenarios that help employees identify potential hazards without the risks associated with actual operations. This immersive experience fosters an environment where workers can practice decision-making skills in high-pressure situations, ultimately leading to improved safety protocols and reduced workplace accidents. Moreover, as companies adopt these innovative tools, they set a foundation for continuous improvement by analyzing the data generated from these simulations. This data analysis allows firms to refine their processes over time, adhering closely to industry standards while optimizing production efficiency.

The Long-Term Benefits of VR Adoption

Incorporating virtual reality solutions into staff training programs not only enhances engagement but also significantly boosts retention rates among employees. Traditional methods often fail to captivate learners’ attention; however, VR training immerses users in interactive environments tailored specifically for their roles within the organization. For instance, when utilizing these advanced technologies for defect detection in manufacturing processes, workers are better equipped to recognize flaws early on—reducing waste and ensuring higher product quality. Furthermore, the incorporation of automation technology alongside VR systems streamlines workflows by creating seamless connections between various stages of production. As organizations witness firsthand improvements in operational performance through enhanced learning experiences and process optimization techniques facilitated by VR applications, they are likely to invest more heavily into such innovations.

Driving Cultural Change Through Innovative Practices

The shift towards embracing VR manufacturing practices signifies not just technological advancement but also a cultural evolution within businesses committed to excellence in quality control and risk management strategies. By prioritizing ongoing education through virtual platforms, companies cultivate an atmosphere where continuous improvement is expected rather than merely encouraged—a crucial mindset needed as industries face increasing global competition and evolving demands from consumers regarding product integrity. Additionally, adopting such forward-thinking practices can yield long-term benefits beyond immediate productivity gains; it positions organizations as industry leaders who value employee development while maintaining strict adherence to compliance guidelines related to safety procedures underpinned by data-driven insights.

In conclusion, leveraging virtual reality technologies facilitates remarkable advancements across numerous facets of business operations—from refining employee training initiatives aimed at reducing errors during critical tasks like defect detection—to fostering organizational cultures devoted entirely toward achieving superior outcomes based on solid core principles stemming directly from innovative engineering designs integrated seamlessly throughout existing frameworks used today across various sectors globally alike!

In the manufacturing sector, ensuring quality control is paramount for success. However, traditional methods often struggle to keep pace with the increasing complexity and precision required in today’s production environments. This is where VR manufacturing quality control systems come into play, offering a transformative solution that enhances defect detection and process optimization.

One of the most significant advantages of integrating VR manufacturing techniques into operations is the ability to simulate various workflows within a virtual environment. By doing so, manufacturers can meticulously monitor each stage of their production cycle. This comprehensive oversight not only minimizes errors but also leads to enhanced compliance with industry standards. With real-time visualization of potential issues before they arise on the factory floor, organizations can take proactive measures that significantly reduce costly recalls or rework.

Moreover, these innovative manufacturing systems leverage automation technology to streamline manual inspections while providing valuable data analysis insights tailored specifically for individual operational needs. As companies adopt advanced techniques such as immersive training modules embedded within these VR solutions, staff members can elevate their skills without disrupting ongoing processes. This capability becomes invaluable in fostering a workforce adept at navigating complex challenges effectively.

The implications extend beyond immediate benefits; implementing virtual reality solutions nurtures a culture focused on continuous improvement and proactive risk management. By embracing such innovations, manufacturers not only tackle current obstacles but also position themselves favorably for future advancements in automated inspection methodologies and performance analytics—all aimed at consistently delivering superior product quality.

FAQ:

Q: How do VR manufacturing quality control systems improve defect detection?

A: These systems allow manufacturers to visualize potential defects in real time during various stages of production within a virtual environment, enabling more accurate monitoring and timely interventions.

Q: What role does automation technology play in VR manufacturing?

A: Automation technology streamlines manual inspections by allowing for faster data collection and analysis while reducing human error rates during quality assessments.

Q: Can staff be trained using VR without interrupting production?

A: Yes, immersive training modules embedded within VR solutions enable employees to enhance their skills effectively without compromising ongoing operations or productivity levels.

Leave A Comment